- Guides

Drain Jetting Equipment Guide

Drainage vehicles have evolved in recent years, with multipurpose vans that can be operated by a single person becoming much more the norm. These types of made-to-measure vehicles are designed and equipped to carry out multiple tasks in a single visit.

Single-resolution is a phrase often used in relation to drain inspection, cleaning and repair within a single visit. To achieve this, vehicles need to remain within weight restrictions whilst carrying additional equipment, such as CCTV inspection units, ancillary drain cleaning tools and drain relining kits.

What's clear is that contractors in the drainage sector are increasingly turning to lightweight, compact diesel and petrol jetters with pump capacities similar to larger units. Many of these feature-rich, modern machines can be supplied in space-saving stack systems and include radio remote control systems – an essential part of single-person operations.

Carrying additional tools and equipment means that more than ever, van payload is a key consideration. For design engineers, this has involved taking a stripped-back approach to reduce the weight and size of the jetting units.

Contents

STAGE V WATER JETTERS

European Stage V emissions regulations have brought about significant changes in the manufacture of jetting equipment. The new regulations relating to NRMM engines (non-road mobile machinery) came into force in 2019/20 and apply to all engines, with a particular focus on diesel engines from 0 to 56 kW.

| Engine Type | Typical Power Range | Typical Output Range | Max Pipe Diameter |

|---|---|---|---|

| Petrol | 15 kW - 42.5 kW | 2250 - 3600 psi @ 16 - 22 gpm | 450 mm |

| Stage V Diesel (above 18.5 kW) | 18.5 kW - 49 kW | 2250 - 3600 psi @ 16 - 28 gpm | 600 mm |

| Stage V Diesel (below 18.5 kW) | Up to 18.5 kW | 3000 - 2100 psi @ 10 - 13 gpm | 450 mm |

PETROL ENGINES

The move away from diesel-powered, high-performance jetting machines has coincided with the availability of more efficient and reliable fuel injection petrol engines. Although smaller petrol jetters have been in circulation for many years, new lightweight EFI engines offer improved torque, and performance figures that are comparable to larger diesel engines.

DIESEL ENGINES

Diesel jetters with a power range below 18.5 kW fall within the Stage V requirements for standard engines. Improved pump and engine performance mean that many of these models are suitable for most common drain and sewer cleaning tasks. Where more power is required (above 18.5 kW) regulations dictate the use of common-rail diesel engines fitted with a DPS filter.

STAGE V: WHY IT’S IMPORTANT

The requirement to reduce emissions by introducing cleaner, greener solutions is the new reality for the drainage sector. All new machines built after the Stage V deadlines must comply with the regulations, meaning that many popular diesel models can no longer be supplied. Alongside these new emissions regulations, individual local authorities have implemented carbon reduction methods such as Low and Ultra-low Emission Zones (ULEZ). In cities such as London, where schemes are already running, that means that contractors need to be aware of potential levies and fines for using non-compliant NRMM machines with a power rating that falls outside the regulatory limits.

TYPES OF DRAIN + SEWER JETTERS

Choosing a high-pressure machine is dependent on the type of tasks it will need to perform. Performance is often the first consideration, though the weight and size of the unit has become increasingly important, with many contractors choosing to also carry smaller units for use in domestic or confined spaces.

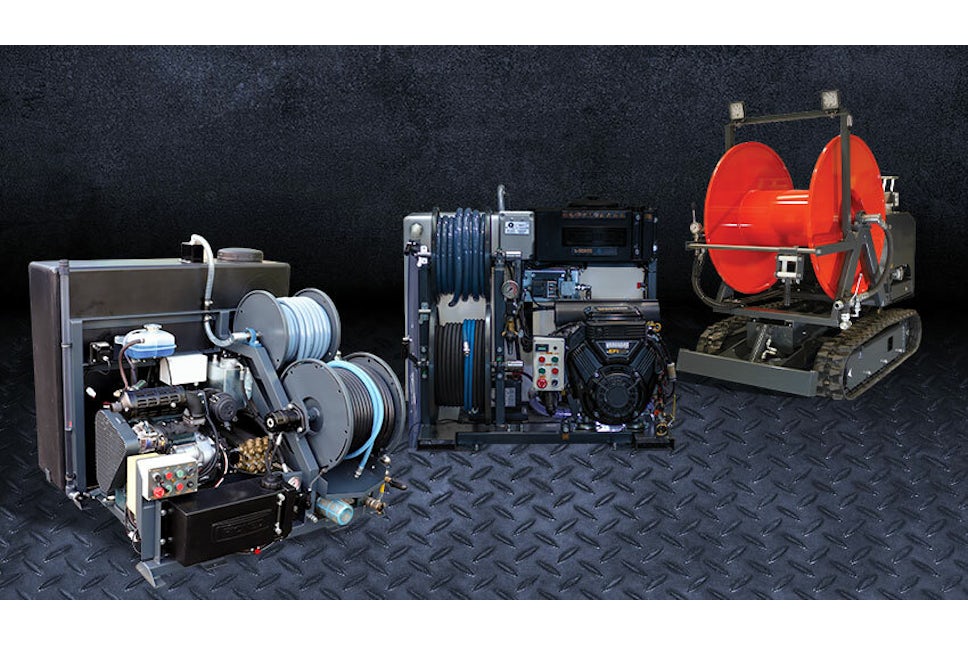

VAN-PACK WATER JETTERS

Suitable for drains up to 600mm, van-pack jetters are skid-mounted for simple installation in a wide range of commercial vehicles. Modern drain jetter design is focused on developing lightweight and compact solutions without compromising on pump performance. New machines are supplied with Stage V-compliant petrol or diesel engines.

STACK + BESPOKE JETTERS

Offering the same specification and level of performance as van-pack jetters, stack and bespoke jetters maximise vehicle access, space and payload. They are suited to everyday use in sewers and drains and can be easily modified to meet requirements, including stack and split units and customised parts and mountings.

PORTABLE WATER JETTERS

Ideal for domestic and light commercial jetting in areas with limited working space, portable jetters are often powered by a small petrol engine or electric motor. Suited to jetting drains and sewers up to 200mm, they can be connected directly to a domestic water supply. In some models, the hose reel can be detached for working in confined spaces.

TRAILER JETTERS

Trailer jetters are comparable in specification to van-pack jetters and are available with a range of engines and pressure/flow capacities for sewers up to 600mm. Modern trailer jetters utilise a range of features for improved performance road-handling and noise reduction, including aerodynamic frames and interconnected water tanks.

FEATURES OF A JETTING MACHINE

MODERN DRAIN JETTERS

Advancements in jetting equipment have seen the creation of more efficient jetters, bespoke parts and the adoption of single-person operation using wireless remote control systems.

PRESSURE + FLOW

The chart below represents some typical drain jetter pressure and flow values

| MOTOR | FUEL | PSI (PRESSURE) | GPM (FLOW) | PIPE SIZE |

|---|---|---|---|---|

| 18kW (23 HP) | Diesel/Petrol | 3,000 | 8 | Up to 200mm |

| 18.5kW (25 HP) | Diesel/Petrol | 3,000 | 9 | Up to 250mm |

| 27.5kW (37 HP) | Diesel/Petrol | 3,000 | 12 | Up to 300mm |

| 27.5kW (44 HP) | Diesel/Petrol | 3,625 | 13 | Up to 350mm |

| 33kW (47 HP) | Diesel/Petrol/PTO/Electric | 3,000 | 16 | Up to 450mm |

| 49kW (65 HP) | Diesel | 4,000 | 18 | Up to 600mm |

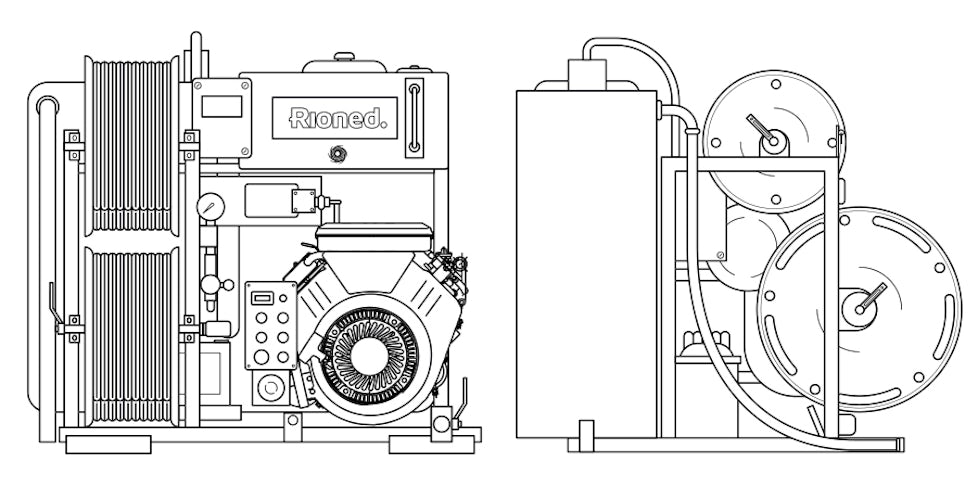

A. HIGH-PRESSURE PUMPS

The jetter engine generally powers the high-pressure water pump to produce water under pressure. Modern direct-drive triplex plunger pumps offer smooth, continuous water flow and pressure. Integrated pressure unloaders enhance pump protection and prolong its life cycle.

B. HYDRAULIC HOSE REELS

A hydraulic hose reel significantly reduces the effort needed to operate a hose reel, whilst operator safety is further improved with the addition of a hose reel locking mechanism. Some jetters feature pivoting reels to allow easier access to drain openings.

C. FILLING HOSE + TANK

Most jetters are equipped with an integrated filling hose, mounted on a hand-operated reel for better storage. Water tanks, in a range of capacities, are often mounted on the frame behind the engine and can also be installed independently to aid weight distribution in the vehicle.

D. REMOTE CONTROL

Wireless remote control systems allow engineers to work more safely, efficiently and with greater control. Modern dual-brand remote control kits mean that pressure and flow settings can be fine-tuned to reduce running time and water usage.

E. SYSTEM PROTECTION

High-pressure jetters feature a number of components designed to reduce potential damage to the machine and extend its life cycle. These typically include run-dry protection systems, unloader valves, and anti-freeze systems and valves.

F. SYSTEM ENHANCEMENTS

Jetters can be fitted with pulsator systems that vibrate to reduce hose drag and propel the nozzle quicker and further along the pipeline. Hot water systems can also be integrated in jetting systems and are popular for the removal of fat deposits in drains and for cleaning street graffiti.

DRAINAGE VEHICLE CONVERSIONS

CUSTOM INTERIORS

Contractors are increasingly turning to bespoke vehicle conversions to provide space-saving solutions for their jetting equipment. Popular conversions include the installation of inverters, lighting and increased storage for tools and ancillary equipment.

1. INVERTER INSTALLATIONS

One of the most important additions to a jetting vehicle is a power inverter, which converts the vehicle’s battery power (DC) into alternating current (AC). Most electric tools used by contractors use 110v or 240v AC power, and operating or recharging these tools from the van is only possible with an inverter running from the vehicle’s battery supply.

2. ANCILLARY EQUIPMENT

To undertake all aspects of drainage work, contractors need to carry a wide range of additional equipment, such as CCTV crawler and push-rod systems, PPE and welfare kits, and drain rods. Multipurpose van-packs are designed to carry a wide range of tools and ancillary equipment.

3. VAN LINING MATERIALS

Lightweight vehicle lining systems play an important part in minimising the weight of a vehicle, with modern, composite materials offering considerable weight savings.

- Spray Linings: Usually a two-part polymer/catalyst spray system that provides a durable, water-resistant, airtight and non-slip surface without losing space.

- Composite Boards: Strong, flexible and 50% lighter than plywood, polypropylene boards combine several layers for extra thermal resistance and strength.

4. LIGHTING

A well-lit area is best for both safety and productivity when working at night or in a bad light. Van-pack vehicles mainly use low energy internal and external LED lights, including interior strip and spotlights and exterior warning beacons and lamps for illuminating working areas.

5. STORAGE OPTIONS

An imbalance in vehicle weight distribution can affect both fuel efficiency and road handling. Water tanks and storage units can be positioned to optimise weight distribution, while still providing adequate storage for a wide range of equipment and tools.

- Guides