- Products

Breathing New Life into Drain Jetting Equipment with Andy Guest Refurbishment Solutions

Running a drainage business smoothly hinges on having reliable equipment. However, amidst economic uncertainties, investing in new machinery can feel like a gamble for contractors.

Fortunately, there's a practical alternative: refurbishing and upgrading existing equipment. At Andy Guest Jetters, our seasoned engineers excel in this cost-effective solution, breathing fresh life into ageing jetting equipment.

This blog explores how the AGJ team transformed a trailer jetter into a new van-pack machine for Manchester-based drainage and plumbing service Absolute Drainage.

Transforming a Trailer Jetter into a Van-Pack

Absolute Drainage approached us with a recently purchased trailer jetter that had previously been used in the agriculture sector. They requested that we convert the unit into a jetting system that could be installed in a 3.5t van.

The trailer unit was powered by a Kohler 2204 four-cylinder diesel engine and pump producing 3600psi @13gpm. Although the engine and pump required a thorough service and some new parts, they were still in good condition for tough drain cleaning tasks.

Refurbishing & Reframing the Jetter

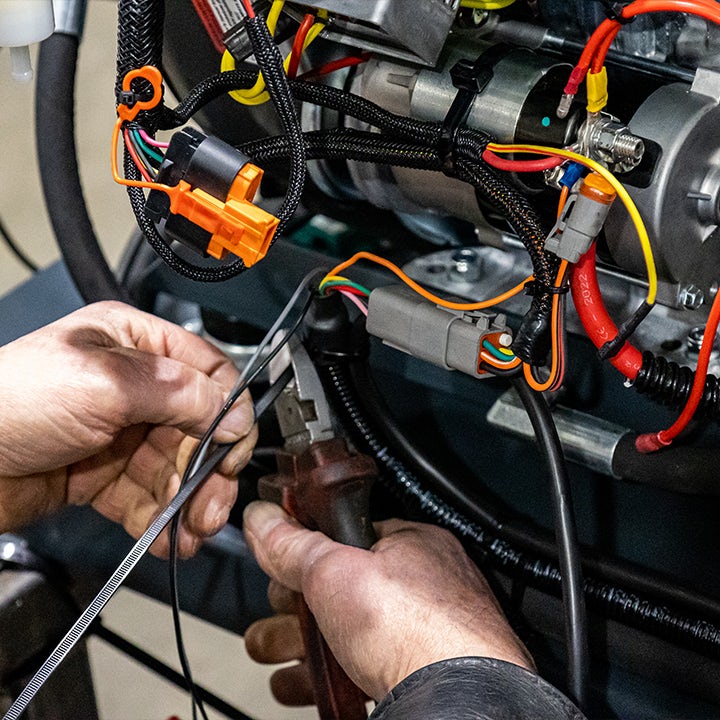

Our experienced technicians began by thoroughly inspecting the engine, pump and other components on the trailer jetter. After determining a schedule of refurbishment and replacements, they meticulously disassembled the jetter, servicing the engine and replacing worn parts to ensure the engine operated at peak performance.

Next came the exciting part: the reframe. The refurbished Kohler 2204 engine, pump and radiator were integrated into a custom-built van-pack frame with an additional filling hose reel. The skid-mounted unit was designed and built for ease of installation in a 3.5-tonne van.

Alongside the new frame, new components were added to the package, including a 500lt water tank, fuel tank and unloader valve to replace the old burst disc system, resulting in a fully operational van-pack jetter ready to tackle any drainage challenge.

Benefits of Jetter Refurbishments

here are several advantages to refurbishing existing drainage equipment:

- Cost-Effectiveness: Refurbishing the existing engine significantly reduced the overall cost compared to purchasing a new high-pressure drain and sewer jetter.

Environmental Sustainability: Reusing an engine minimises waste and prolongs the life of reliable equipment.

Proven Performance: Servicing and refurbing good quality engines offers dependable power and performance.

- Versatility: The reframed machine provided the client with a powerful, multi-purpose van-pack jetting solution.

Revitalise Your Jetting Equipment

This case study demonstrates the potential benefits of refurbishing equipment. By breathing new life into older equipment, we enable businesses to upgrade or add to their high-performance jetting solutions without the cost of buying new equipment..

So, if you have a dependable engine that needs refurbishing, reframing or upgrading, we can help you explore cost-effective options to get the most from your equipment. Contact us today to discuss how we can breathe new life into your jetting equipment.

Find out more about our repair, servicing and refurbishment solutions

- Products